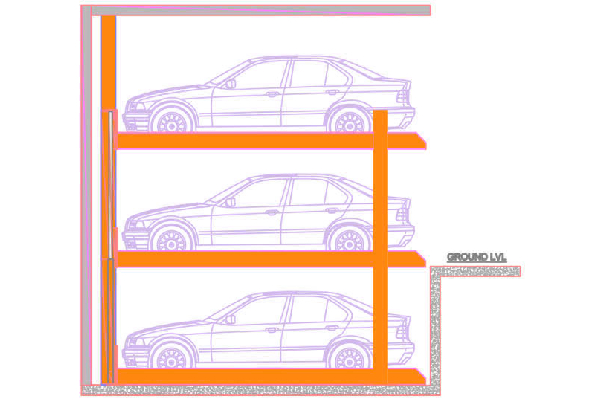

Three Level Stack With One Pit Level

This system offer parking for three cars one on the ground level, one level above ground and one car in the Pit. For removing the car parked on the first level or the Pit level, Ground level car must be removed.

Please Note :- Maximum height of the pit level depends upon the clear height above the ground level

| TYPE | Three level Stack with one pit level |

|---|---|

| MODELS | E3BS/E3BM/E3BB |

| NO. OF CAR PER UNIT | 3 Cars |

| LIFTING CAPACITY | 2000 Kg [ Per Car Weight] |

| LIFTING TIME | 2 m/min (each stack) |

| OPERATION | Hydraulic Power Pack, Two Cylinder with Key/Push button operation. |

| POWER SUPPLY | 415 V, 3 phase, 50 Hz |

| POWER CONSUMPTION | Up to 0.03 units per stack operation (approx.) |

Specification Table

Standard Features

Requirements from Client

Specification Table

MODEL | SYSTEM | PLATFORM | PLATFORM | LOWER CAR | LIFTING | CAR |

E3BS | 2300 X 4500 | ALL LEVEL | MAX – 4100 | ALL LEVEL | Hydraulic / | Small Cars |

E3SM | 2500 X 5500 | ALL LEVEL | MAX – 5100 | ALL LEVEL | Hydraulic / | Small Cars/ |

E3SB | 2700 x 5500 | ALL LEVEL | MAX – 5200 | ALL LEVEL | Hydraulic / | Mid Sized Sedan/ |

Standard Features

- Three Platforms per system.

- Color scheme for the System can be provided as per the Client’s requirement.

- Hot dipped Galvanized Corrugated floor plates on platforms to reduce dead weight and increase durability.

- Two sets of hydraulic cylinders will be provided.

- Chain supported balancing and lifting Mechanism

- Compact Power pack system with enclosed motor and rubber bush fittings for reduced noise levels.

- Optional Photo sensor for the middle car to prevent accidental lowering of upper stack or lifting of the lower stack.

- Electromagnetic locking mechanism to prevent unwanted lowering of upper stacks.

- Limit switches to restrict the travel height by Auto cutting off the motor.

- Remote switch box with Key/Push button for easy operation.

- Emergency Shutdown switch.

Requirements from Client

- Parking area allotted must be cleared with no obstructions.

- Civil work in Pit to be completed with appropriate drainage system provided to prevent water accumulation.

- Base area of the parking space allotted shall be Concrete with minimum strength of M20.

- Pit area provided should be clean and free of any accumulated water.

- Appropriate lighting to be provided within the pit and working area.

- Additional space to be provided for storing and installing the Power Pack system.

- While erection of the system client should provide storage facilities for keeping our tools and other valuable parts of the system.

- Temporary Electrical connection must be provided at the time of erection and installation of the systems.

- 12 amps MCB and Main Electrical Connection (or 4 Pole RCBO) along with electrical cable fitting must be provided from the Main Power supply to the parking systems with 3Ph 415V AC, 50Hz with Neutral and Earth (3Ph+N+E).

- Incoming Cable Size should be at least 5 Core x 2.5 sq.mm. Flexible Copper multi Core cable (3PH+N+E) from Main Switch to Control Panel.

- In case of Parking Installed in open to Sky location, it is recommended to have a weather covering over the installation to prevent damage to the electronics / mechanism due to weathering.